JPI7S-15-99 Kelas 300 Bebibir

Flange ialah sejenis bahagian penyambung yang boleh menyambungkan paip, injap dan peralatan. Kelebihan bebibir termasuk: 1. Fleksibiliti yang baik: sambungan bebibir mudah dibongkar dan disesuaikan, yang sesuai untuk penyelenggaraan dan penggantian peralatan. 2. Pengedap yang baik: Sambungan bebibir boleh menggunakan gasket atau gasket yang berbeza untuk memenuhi keperluan cecair dan tekanan yang berbeza, dan mempunyai pengedap yang baik. 3. Kapasiti galas tekanan yang kuat: Sambungan bebibir boleh menahan tekanan dalaman dan luaran yang besar, menjadikannya sesuai untuk persekitaran kerja yang keras seperti suhu tinggi, tekanan tinggi dan kakisan. 4. Kebolehpercayaan yang tinggi: Oleh kerana sambungan bebibir disambungkan oleh bolt dan nat, ia dapat memastikan ketegasan sambungan, dengan itu meningkatkan kestabilan dan kebolehpercayaan peralatan dan saluran paip. 5. Kebolehsuaian yang kuat: Sambungan bebibir boleh dipilih daripada pelbagai bahan, saiz dan spesifikasi mengikut keperluan, dan boleh menyesuaikan diri dengan pelbagai persekitaran dan keperluan kerja.

The JPI7S-15-99 Class 300 flanges manufacturing method has countless blessings and characteristics:

High Quality: The manufacturing technique of JPI7S-15-99The manufacturing technique of JPI7S-15-99 Class 300 flanges provides a number of benefits and characteristics:

High-quality materials: The flanges are produced the usage of magnificent materials such as carbon metal or stainless steel, making sure sturdiness and resistance to corrosion.

Accurate dimensions: The manufacturing technique ensures that the flanges are manufactured with particular dimensions, permitting for suitable suit and compatibility with otherThe JPI7S-15-99 Class 300 flanges manufacturing system presents countless blessings and showcases sure characteristics. Here are some of them:

High-quality production: The manufacturing technique ensures that JPI7S-15-99 Class 300 flanges are manufactured with excessive precision and foremost quality. This lets in for dependable overall performance and sturdiness of the flanges.

Compliance with standards: The manufacturing system follows the JPI7S-15-99 fashionable for Class 300 flanges. This ensures that the flanges meet the required specs and can be used in a vast vary of functions besides any compatibility issues.

Thorough checking out and inspection: The manufacturing technique consists of rigorous checking out and inspection processes to make sure that the flanges meet the essential requirements and fantastic requirements. This helps in handing over defect-free merchandise to the customers.

Efficient manufacturing techniques: The manufacturing technique makes use of environment friendly manufacturing techniques, such as superior machining and fabrication methods. This permits for quicker manufacturing and ensures that the flanges are manufactured with utmost accuracy.

Material options: The manufacturing procedure permits for the use of a number materials, such as carbon steel, stainless steel, and alloy steel, based totally on the particular necessities of the customers. This affords flexibility in phrases of fabric selection, enabling the flanges to be appropriate for exclusive working conditions.

Corrosion resistance: The flanges produced thru this technique are designed to be corrosion resistant, making them appropriate for use in environments the place publicity to moisture, chemicals, or different corrosive components is likely.

Wide vary of sizes: The manufacturing manner can accommodate the manufacturing of JPI7S-15-99 Class 300 flanges in a broad range of sizes, from small to giant diameters. This makes the flanges appropriate for numerous industrial applications.

Customization options: The manufacturing technique lets in for customizable elements and specs primarily based on the precise necessities of the customers. This ensures that the flanges can be tailor-made to meet the special desires of one of a kind projects.

Overall, the JPI7S-15-99 Class 300 flanges manufacturing method affords a mixture of quality, precision, and flexibility, making it a dependable desire for a number of industrial applications.

-99 Class 300 flanges manufacturing method has countless blessings and characteristics:

High Quality: The manufacturing technique of JPI7S-15-99The manufacturing technique of JPI7S-15-99 Class 300 flanges provides a number of benefits and characteristics:

High-quality materials: The flanges are produced the usage of magnificent materials such as carbon metal or stainless steel, making sure sturdiness and resistance to corrosion.

Accurate dimensions: The manufacturing technique ensures that the flanges are manufactured with particular dimensions, permitting for suitable suit and compatibility with otherThe JPI7S-15-99 Class 300 flanges manufacturing system presents countless blessings and showcases sure characteristics. Here are some of them:

High-quality production: The manufacturing technique ensures that JPI7S-15-99 Class 300 flanges are manufactured with excessive precision and foremost quality. This lets in for dependable overall performance and sturdiness of the flanges.

Compliance with standards: The manufacturing system follows the JPI7S-15-99 fashionable for Class 300 flanges. This ensures that the flanges meet the required specs and can be used in a vast vary of functions besides any compatibility issues.

Thorough checking out and inspection: The manufacturing technique consists of rigorous checking out and inspection processes to make sure that the flanges meet the essential requirements and fantastic requirements. This helps in handing over defect-free merchandise to the customers.

Efficient manufacturing techniques: The manufacturing technique makes use of environment friendly manufacturing techniques, such as superior machining and fabrication methods. This permits for quicker manufacturing and ensures that the flanges are manufactured with utmost accuracy.

Material options: The manufacturing procedure permits for the use of a number materials, such as carbon steel, stainless steel, and alloy steel, based totally on the particular necessities of the customers. This affords flexibility in phrases of fabric selection, enabling the flanges to be appropriate for exclusive working conditions.

Corrosion resistance: The flanges produced thru this technique are designed to be corrosion resistant, making them appropriate for use in environments the place publicity to moisture, chemicals, or different corrosive components is likely.

Wide vary of sizes: The manufacturing manner can accommodate the manufacturing of JPI7S-15-99 Class 300 flanges in a broad range of sizes, from small to giant diameters. This makes the flanges appropriate for numerous industrial applications.

Customization options: The manufacturing technique lets in for customizable elements and specs primarily based on the precise necessities of the customers. This ensures that the flanges can be tailor-made to meet the special desires of one of a kind projects.

Overall, the JPI7S-15-99 Class 300 flanges manufacturing method affords a mixture of quality, precision, and flexibility, making it a dependable desire for a number of industrial applications.

Nominal paip Saiz |

Di luar Dia.daripada Bebibir |

Dia of Bore |

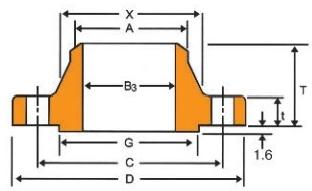

Dia.of Hub di Bevel A |

Dia.of Hub at Asas |

Dia.daripada Dibesarkan Muka |

tebal daripada Bebibir |

Jejari daripada Filet |

|||||||||||

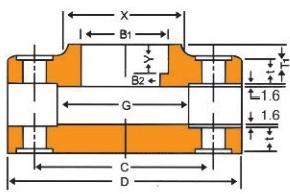

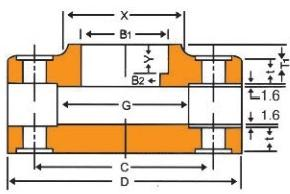

Tergelincir Soket B1 |

Lap-Bersama B2 |

Leher Kimpalan, Soket B₃ |

||||||||||||||||

JPI |

ANSI |

|||||||||||||||||

A |

B |

D |

JPI |

ANSI |

JPI |

ANSI |

SCH40 |

SCH80 |

SCH160 |

SCH40 |

SCH80 |

SCH160 |

JPI |

ANSI |

X |

G |

t |

R |

15 20 25 |

h % 1 |

95 117 124 |

22.2 27.7 34.5 |

22.4 27.7 34.6 |

23.4 28.9 35.6 |

22.9 28.2 35.1 |

16.1 21.4 27.2 |

14.3 19.4 25.0 |

12.3 16.2 21.2 |

15.8 20.9 26.6 |

13.9 18.8 24.3 |

11.8 15.6 20.7 |

21.7 27.2 34.0 |

21.3 26.7 33.5 |

38.1 47.8 53.8 |

35.1 42.9 50.8 |

14.2 15.7 17.5 |

3 3 3 |

(32) 40 50 |

(14) 1% 2 |

133 155 165 |

43.2 49.1 61.1 |

43.2 49.6 62.0 |

44.3 50.4 62.7 |

43.7 50.0 62.5 |

35.5 41.2 52.7 |

32.9 38.4 49.5 |

29.9 34.4 43.1 |

35.1 40.9 52.5 |

32.5 38.1 49.3 |

29.5 34.0 42.9 |

42.7 48.6 60.5 |

42.2 48.3 60.5 |

63.5 69.9 84.1 |

63.5 73.2 91.9 |

19.1 20.6 22.4 |

5 6 8 |

65 80 (90) |

2% 3 (3%) |

190 210 229 |

77.1 90.0 102.6 |

74.7 90.7 103.4 |

78.7 91.6 104.1 |

75.5 91.4 104.2 |

65.9 78.1 90.2 |

62.3 73.9 85.4 |

57.3 66.9 76.2 |

62.7 77.9 90.1 |

59.0 73.7 85.5 |

54.0 66.7 |

76.3 89.1 101.6 |

73.2 88.9 101.6 |

100.1 117.5 133.4 |

104.6 127.0 139.7 |

25.4 28.4 30.2 |

8 10 10 |

100 (125) 150 |

4 (5) 6 |

254 279 318 |

115.4 141.2 166.6 |

116.1 143.8 170.7 |

116.9 143.0 168.4 |

116.9 144.6 171.5 |

102.3 126.6 151.0 |

97.1 120.8 143.2 |

87.3 108.0 128.8 |

102.3 118.2 154.2 |

97.2 122.3 146.3 |

87.3 109.6 131.8 |

114.3 139.8 165.2 |

114.3 141.2 168.4 |

146.1 177.8 206.2 |

157.2 185.7 215.9 |

31.8 35.1 36.6 |

11 11 13 |

200 250 300 |

8 10 12 |

381 444 521 |

218.0 269.5 321.0 |

221.5 276.4 327.2 |

219.5 271.7 322.8 |

222.3 277.4 328.2 |

199.9 248.8 297.9 |

190.9 237.2 283.7 |

170.3 210.2 251.9 |

202.7 254.5 303.2 |

193.7 242.9 288.9 |

173.1 215.9 257.2 |

216.3 267.4 318.5 |

219.2 273.1 323.9 |

260.4 320.8 374.7 |

269.7 323.9 381.0 |

41.1 47.8 50.8 |

13 13 13 |

350 400 450 |

14 16 18 |

584 648 710 |

358.1 409.0 460.0 |

359.2 410.5 461.8 |

360.2 411.3 462.4 |

333.4 381.0 428.6 |

317.6 363.6 409.6 |

284.2 325.4 366.8 |

333.3 381.0 428.7 |

317.5 363.6 409.6 |

284.2 325.5 366.7 |

355.6 406.4 457.2 |

355.6 406.4 457.2 |

425.5 482.6 533.4 |

412.8 469.9 533.4 |

53.8 57.2 60.5 |

13 13 13 |

|

500 600 |

20 dua puluh empat |

775 914 |

511.0 613.0 |

513.1 616.9 |

514.4 616.0 |

477.8 574.6 |

455.6 547.8 |

408.0 490.6 |

477.8 574.8 |

455.6 547.7 |

408.0 490.6 |

508.0 609.6 |

508.0 609.6 |

587.2 701.5 |

584.2 692.2 |

63.5 69.9 |

13 13 |

|

Panjang Hab Thru |

Kedalaman daripada Soket |

Penggerudian |

Slaid daripada Dibesarkan Muka untuk cincin Meterai |

Pitch Dia.or Ring & Alur |

Cincin

Dari. |

Jenis RTJ |

Anggaran Berat (kg) |

Nominal paip Saiz |

||||||||||

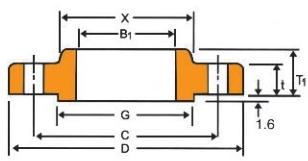

Benang Soket Slip-on |

pusingan

Meterai |

Kimpalan Leher |

Hari Bulatan Bolt |

Nombor daripada Bolt |

Dia daripada Bolt lubang |

Kedalaman daripada Alur |

Lebar daripada Alur |

Jejari daripada Alur |

WN |

S.0 |

SW |

BL |

||||||

T; |

T2 |

T |

DAN |

C |

N |

K(min) |

P |

DAN |

F |

4 |

A |

B |

||||||

22.2 25,4 27.0 |

22.2 25.4 27.0 |

52.4 57.2 61.9 |

9.5 11.1 12.7 |

66.5 82.6 88.9 |

4 4 4 |

16 19 19 |

51.0 63.5 70.0 |

34.14 42.88 50.80 |

R11 R13 R16 |

5.56 6.35 6.35 |

7.14 8.74 8.74 |

0.8 0.8 0.8 |

0.80 1.25 1.58 |

0.65 1.10 1.35 |

0.67 1.12 1.39 |

0.65 1.09 1.38 |

15 20 25 |

C % 1 |

27.0 30.2 33.3 |

27.0 30.2 33.3 |

65.1 68.3 69.8 |

14.3 15.9 17.5 |

98.6 114.3 127.0 |

4 4 8 |

19 dua puluh dua 19 |

79.5 90.5 108 |

60.32 68.28 82.55 |

R18 R20 R23 |

6.35 6.35 7.92 |

8.74 8.74 11.91 |

0.8 0.8 0.8 |

2.05 2.93 3.40 |

1.69 2.54 2.92 |

1.74 2.60 3.02 |

1.82 2.70 3.18 |

(32) 40 50 |

(114) (1 untuk 2 |

38.1 42.9 44.5 |

38.1 43.9 44.5 |

76.2 79.4 81.0 |

19.0 20.6 22.2 |

149.4 168.1 184.2 |

8 8 8 |

dua puluh dua dua puluh dua dua puluh dua |

127 146 159 |

101.60 123.82 131.78 |

R26 R31 R34 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

5.10 7.01 8.71 |

4.24 5.94 7.90 |

4.43 6.21 |

4.86 6.90 8.79 |

65 80 (90) |

2% 3 (3%) |

47.6 50.8 52.4 |

47.6 50.8 52.4 |

85.7 98.4 98.4 |

23.8 23.8 27.0 |

200.2 235.0 269.7 |

8 8 12 |

dua puluh dua dua puluh dua dua puluh dua |

175 210 241 |

149.22 180.98 211.12 |

R37 R41 R45 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

11.3 15.1 19.6 |

9.71 12.4 16.2 |

11.6 15.5 21.2 |

100 (125) 150 |

4 (5) 6 |

|

61.9 66.7 73.0 |

61.9 95.3 101.6 |

111.1 117.5 130.2 |

31.8 33.3 39.7 |

330.2 387.3 450.9 |

12 16 16 |

26 29 32 |

302 356 413 |

269.88 323.85 381.00 |

R49 R53 R57 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

30.3 44.3 64.1 |

24.8 35.9 51 |

34.5 53.9 78.9 |

200 250 300 |

8 10 12 |

|

76.2 82.6 89.9 |

※111.3 ※120.7 ※130.0 |

142.9 146.0 158.8 |

41.3 44.5 49.2 |

514.4 571.5 628.7 |

20 20 dua puluh empat |

32 35 35 |

457 508 575 |

419.10 469.90 533.40 |

R61 R65 R69 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

88.3 113 138 |

70.1 90.4 109 |

106 139 175 |

350 400 450 |

14 16 18 |

|

95.2 106.4 |

※149.7 ※152.4 |

161.9 168.3 |

54.0 63.5 |

685.8 812.8 |

.dua puluh empat dua puluh empat |

35 42 |

635 749 |

584.20 692.15 |

R73 R77 |

9.52 11.13 |

13.49 16.66 |

1.5 1.5 |

169 248 |

136 204 |

222 340 |

500 600 |

20 dua puluh empat |

|

Kilang Kami

Pengosongan Bahan Mentah

Pemeriksaan Makmal

Menempa & Menempa dan Menekan

Pemprosesan Mesin

Penghormatan Oalifikasi Perusahaan